Why Most Manufacturing Software Fails Mid-Market Teams…And How a Composable ERP Doesn’t

You’ve seen the demos. The polished interfaces, the endless feature lists, the promises of a streamlined future. The sales team was brilliant, showcasing a world where every process was optimized, every report was instantaneous, and every decision was data-driven. You invested, onboarded your team, and prepared for transformation. But now, months later, the promised efficiency feels like a mirage. Your team is frustrated, workarounds are the new norm, and the “solution” is starting to feel like the problem.

The head of shop floor operations just left your office, complaining that the new MRP system requires three extra steps to log a custom quality check—the very quality check that differentiates your product in the market. Your finance team is spending the first week of every month manually reconciling inventory numbers between the new ERP and the warehouse management system because they refuse to sync correctly. The “real-time” dashboard you were so excited about? It’s updated once every 24 hours, rendering it useless for tactical decision-making.

Sound familiar? You’re not alone. The landscape for large enterprises is littered with manufacturing software that over-promises and under-delivers. The critical failure point, however, is rarely the software itself. It’s the flawed premise that a generalized one-size-fits-all solution can reinforce your unique, intricate processes. The real issue is that most off-the-shelf software was built for

a process but not for your process. And the relentless effort to force a fit is where the system breaks your workflows, rather than reinforcing them.

The Myth of the “Perfect” Off-the-Shelf Solution

For a data-driven leader in a mid-market manufacturing or retail company, the goal is clear: leverage data for a competitive edge. Streamlining your process is a high priority and you’re focused on optimizing your supply chain, achieving accurate forecasting, and enhancing operational efficiency. The challenge is that your operations are a complex mix of legacy systems and modern cloud platforms that fights your process, rather than fixing issues.

Data silos isolate your data, this fragmented data is a significant liability in a world that demands agility and flexibility. This lack of agility takes control of your timelines, changing what was supposed to be an asset into a necessary liability. Your systems become rigid, and your systems take more effort to work around when they are supposed to simplify your processes.

Traditional, monolithic MRP and ERP systems claim to solve this by creating a single, centralized platform. But in reality, they often exacerbate the very problems they promise to fix. They promise to centralize data, but they indirectly lock your systems together and make switches off legacy or inefficient systems more difficult than they need to be.

Where Monolithic Systems Fall Short

- Forced Adaptation Kills Your Competitive Edge

These systems impose a rigid workflow, forcing your team to abandon proven processes for a “standardized” model that doesn’t account for your specific value-add. That unique, multi-point inspection process? The ERP doesn’t have a field for it. That innovative method for reducing material scrap during setup? You have to use a “notes” field as a workaround. This creates friction, slows adoption, and breeds inefficiency.

Waste Reduction is promised but not provided; you’re now wasting time and effort fighting the system, trying to force a fit. You want your processes to be your own, but they can only be what your ERP allows them to be. Your secret sauce gets watered down into a generic recipe, eroding the very thing that makes you better than your competition.

- Creating Deeper, More Frustrating Data Silos

Instead of creating a single source of truth, these rigid systems often compound the problem of fragmented data. They become just another scattered island, when you want technology continent. Information gets trapped within the new software, failing to integrate with your existing data warehouses, Bl tools, and other critical platforms.

Real Time Updates/Data become impossible. The sales team is making promises based on inventory data that’s a day old, leading to stockouts and unhappy customers. Meanwhile, your procurement team over-orders materials because they can’t see the real-time consumption on the factory floor. This isn’t a single source of truth; it’s a fractured mirror, reflecting multiple, conflicting versions of reality and actively preventing you from having clean, standardized, real-time data.

- Hindering True Scalability

Slowdowns from an incompatible ERP prevent your business from scaling at the rate you want.

Scalability, your leaders talk about scalability; they don’t just mean processing more orders. They mean being agile enough to seize new opportunities. What happens when you want to acquire a smaller competitor? Or pivot to a direct-to-consumer model? Or integrate a new, state-of-the-art automation system on the production line? A monolithic ERP turns these strategic moves into year-long, budget-draining nightmares of incompatible integration projects that attempt to force a fit that doesn’t wasn’t intended. The system that was supposed to support growth becomes the anchor holding you back. As your business grows, the issues grow with it.

- The Hidden Price Tag: A Cascade of Unforeseen Costs

The initial software license is just the tip of the iceberg. The real financial drain comes from the endless workarounds. The time your engineers spend building brittle, custom scripts to extract data. The hours your operations team spends on manual data reconciliation. The opportunity cost of decisions made on stale information. This isn’t just inefficient; it’s a direct hit to your bottom line. The goal of Cost-Reduction through technology has led to the creation of new, previously nonexistent costs that counteract any savings generated by your new ERP.

From Forced Fit to Strategic Fit: The Power of Composability

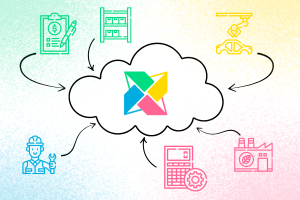

The forward-thinking solution isn’t to find a better off-the-shelf system; it’s to adopt a new approach. Your ecosystem should not be built as a monolithic block, but as a set of interoperable, independent modules—a custom, Composable ERP.

A monolithic ERP could be compared to an all-in-one stereo system from the 1990s. At the time of purchase, it was a convenient, complete package with a radio, cassette deck, CD player, and amplifier all in one unit. But soon, you discover its limitations. When a new technology like music streaming emerges, there’s no way to integrate it. If the CD player breaks, the entire system’s value is compromised, and repair is difficult. You can’t upgrade just the speakers for better sound; you’re locked into the quality and technology of the entire, single unit. Your business must settle for unoptimized legacy systems that cannot hold up to competitors .

A composable architecture, on the other hand, is like a modern, high-end home audio system. You select the best-in-class components from different, specialized manufacturers: a powerful amplifier from one brand, acoustically superior speakers from another, and a high-resolution streaming device from a third. They all connect seamlessly using standard interfaces like HDMI or Wi-Fi (the modern equivalent of APIs). If a new, better streaming technology comes out next year, you can simply swap out that one component without touching the rest of your investment. You have the power to choose the best tool for each specific job, creating a system that is perfectly tailored to your standards and can evolve over time. This model breaks down core functionalities into “composable units” that can be selected and integrated to create a tailored system. It’s a framework designed to be an enabler, not a constraint.

Why Composability is a Game-Changer

#1 Built for Your Process with Granular Track and Trace

A composable approach allows you to track and trace every step of your actual workflow because the system is custom-built around it. For a medical device manufacturer, this means embedding specific FDA compliance checkpoints directly into the production workflow, not as an afterthought. For a food and beverage company, it means having a dedicated module that provides granular, real-time tracking of a specific ingredient batch from supplier to final shipment. This ensures the data is standardized to your preference and reflects reality, providing a real single source of truth.

#2 Scalable by Design with Multi-Domain Capabilities

True Multi purpose scalability is inherent. It’s not just about handling more volume; it’s about handling more complexity. As your business evolves, you can add or swap modules without disrupting the entire system, ensuring your technology stack remains agile. This facilitates the adoption of new technologies and best-of-breed solutions.

This is true MultiDomain thinking. A company that manufactures, distributes, and sells directly to consumers can have best-in-class modules for each of those domains—a manufacturing execution system (MES), a warehouse management system (WMS), and an e-commerce platform—all built on a common, interoperable data core. The agility given to you allows you to stay competitive by allowing you to react faster and with higher accuracy than your competitors.

#3 Eliminates Data Silos for Accurate Real-Time Updates

By leveraging modern integration and APIs, a composable system ensures seamless connectivity between all your platforms. This isn’t just about syncing data overnight; it’s about creating a data fabric where information flows instantly and contextually. When a sale is made on your website, the inventory is updated in the WMS, and the production demand is updated in the MES in seconds. Streamlining these processes provides clean, governed, and integrated datasets needed for transparent, reliable, real-time data and trustworthy AI initiatives.

#4 Drives Tangible Cost-Reduction and Waste Reduction

By eliminating the need for manual workarounds and enabling you to streamline workflows, a composable approach leads to significant operational cost-reduction and a more efficient allocation of resources. Imagine reclaiming thousands of man-hours per year previously lost to manual data entry. Imagine reducing scrap and rework by 10% because your quality control processes are perfectly integrated. Imagine improving forecast accuracy to the point where you can lower inventory carrying costs by 15%. This is where the promise of technology is finally realized.

Stop Forcing the Fit. Start Building Your Advantage.

Your business is unique. Your processes are your competitive advantage. Don’t let rigid software dictate your path forward. It’s time to move beyond the limitations of rigid monolithic solutions and embrace a strategy that offers both flexibility and control.

The path to a composable architecture is a journey, not a flip of a switch. It starts with a strategic shift in mindset:

- Map Your Value Chain: Identify the core processes that truly differentiate you. Where does your team create unique value? These are the areas that demand a tailored solution, not a generic one.

- Audit Your Data Flow: Where are your most painful Data Silos? What information, if available in Real Time, would unlock the most value for your teams Understanding the current state of data fragmentation is the first step toward fixing it.

- Think in Modules, Not Monuments: Start identifying the best-of-breed solutions for specific functions. What’s the best tool for inventory management? For quality assurance? For logistics? The goal is to build a flexible ecosystem, not another rigid monument.

Don’t let fragmented data and inefficient systems hold your enterprise back from its full potential. A composable, interoperable approach is the key to unlocking agility, strengthening compliance, and driving real innovation.

Contact Pivotly today to explore how we can help you build a truly interoperable and AI-ready Manufacturing data ecosystem. Visit www.pivotly.com/request-consultation or call us at (651) 208-9300.